![]()

HAVE A FRIEND who hates dirty pictures. If the slightest scratch should appear on the screen image, his eyes become riveted to it, to the exclusion of all else. Even allowing for some very boring films, this is going a bit far. I have now found a cure for said friend. It comes in a bottle. Called Filmlife.

Filmlife is an exceptional movie film treatment. It cleans, lubricates and conditions in one operation. I will quote extensively from an anonymous paper sent by the manufacturers, giving reasons why their product was considered necessary.

"Due to the nature of motion-picture film it has a tendency to attract or collect dirt and dust particles and this condition is to some extent aggravated by the transport of the film through a projector. It is therefore desirable to find a satisfactory means of eliminating or minimising that hazard.

"For many years it has been an accepted fact that lubrication of processed film improves the projection performance. "

A considerable amount of work has been carried out on various forms of film lubrication. Most have exhibited good antifriction qualities, but have had certain undesirable factors. The experiments have indicated the absolute necessity to employ some form of lubrication."

Projectors without sprockets must take a large proportion of the blame for unnecessary film damage, particularly super 8 models. This is simply because higher gate pressures are needed to ensure image steadiness on the screen.

A few lubricants and the undesirable qualities they possess are listed by the manufacturers of Filmlife and I quote

from these.

1. One of the oldest forms of film treatment is paraffin wax, or a mixture of paraffin and carnuba wax in

trichloroethylene, this being normally applied to the margin of the film to a thickness of about 0.002in. (2

thousandths). The friction coefficient of this material is very good, but during the passage of the film through the

gate of the projector, a great amount of the wax is stripped off and deposited in the gate. This accumulation of wax

at the ingoing part of the gate readily collects dust particles which are abrasive and have a tendency to create film

damage, together with the fact that the wax and dirt build-up causes the projector to require very frequent cleaning.

2. Silicone treatment applied during the development process, prior to the film drying cabinet is quite effective, but

maintaining the chemical bath in the correct condition does present some difficulty, plus the fact that silicones have

a slight fogging effect on unexposed stock.

3. There are several lacquer systems where the treatment is applied separately by applicator rollers to both base

and emulsion surfaces of the film. This form of treatment is rather more as a protection than a lubricant, but some

of them do possess both qualities. This treatment is normally applied to a thickness of 0.0005in.

(1 thou.) and one

can often see evidence of the coating powder coming off when the film passes through a

projector gate which has a high pad pressure, A further hazard with the lacquering system is frequent use of highly

inflammable liquids.

Filmlife was developed to avoid these known disadvantages and to offer more t just a straightforward lubricant. The maker claim that an application of this liquid will provide protection to film, inhibit scratching and, when applied to used copies, eliminate fine scratches, coat the film uniformly an discourage further build up of dirt. Owing to the nature of Filmlife and the infinitely thin coating required, it prevents the treatment from powdering off in the projector gate

So much for the claims. Are they justified The answer is an unqualified yes!

When the sample bottle arrived for testing I hadn't got one of the special velvet cloth which you are supposed to use. Nevertheless I had a go with an old well-washed handkerchief. Although on preliminary examination the film appeared cleaner, this was not the prime purpose of the first test. It would not be fair, I decided, to ask for the full treatment when I was not using the recommended applicator.

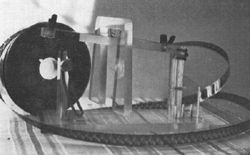

I contented myself with trying the antifriction, lubrication claims. For this test a splendid piece of apparatus was used, Officially it is called a 'Paper Clip Friction Tester'. In case you think I am joking this machine is illustrated in the photograph. Full details of it are to be found in the April 1972 issue of the British Kinematography Sound and Television magazine. Putting it in a nutshell it shows how 'slippery' a film is.

On a length of untreated film the 'PCFT' had to be pushed to make the slider slide, The same length of film was then treated with Filmlife and the test repeated. This time the paper clip slider raced madly down even the slightest incline on the PCFT. Net content with just one type of film, I tried the following: a super 8 colour original, a standard 8 monochrome reversal, a 9.5 colour original, a 16mm monochrome negative and a 16mm colour print. With each type the result was the same, proving that one single (and it must be confessed, haphazard) application of this liquid improves measurably the antifriction properties of the film. As a lubricant Filmlife is a winner.

One application is sufficient, I am told, for many showings of a film, lasting at least and application 18 months to two years storage in the can.

|

|

The Filmlife kit, showing the bottle of solution cloth, together with the we# padded packing. |

The 'Paper Clip Friction Tester' used to test the frictional characteristics of the film before and after the application of the Filmlife solution. |

The special velvet cloth arrived and I was ready to go on to the cleaning and conditioning tests. The method of

application is very simple; the makers suggest the following ten point routine:

1. Filmlife treatment should be applied to the film by means of the special velvet cloth supplied with the bottle.

2. The velvet should be well moistened with the liquid and held in the hand. The film should be drawn slowly through,

in the order of 12 to 15ft per minute, so that both the acetate base and the emulsion surface are treated together.

3. The cloth must be frequently moved to present a new clean surface in order to avoid any scratching which may

occur if dirt is allowed to build up in one place on the cloth.

4. Care should be taken to see that the film is dry

before winding up on to the roll. This is usually ensured by checking that the cleaning cloth is moist and not wet.

5. A skilled operator could use a projector rewind facility to apply the treatment. The moistened velvet cloth is held

lightly between the two spools and the machine then run in the rewind mode. Great care must be exercised during

the winding to ensure that: (a) the film is dry prior to take-up and (b) splices and damaged perforations do not

become caught up in the cloth, resulting in the film being torn.

6. If a film has suffered abrasions during its use, it will benefit from the first application and in severe cases it

should be run twice.

7. The treatment may be applied as many times as required during the life of the film, but the first treatment will

normally last 18 months.

8. NOTE: Due to a slight anesthetic effect of the liquid, it is advisable to carry out the treatment in a reasonably

well ventilated area and not to smoke during the operation.

9. Due to the ingress of dirt and the evaporation of the

liquid the bottle cap must be replaced after use.

10. Spare velvet cloths may be obtained from Film Treatment Limited.

Having followed the simple instructions, I was most surprised to find how grubby the velvet cloth had become. The cleaning operation had certainly removed dirt that I was unaware of on my film. The liquid smells as though it might contain carbon tetrachloride, an efficient film cleaner, but point 8 should be particularly noted - especially not to smoke while using the liquid. (It's a filthy habit anyway. And the money could be better spent on more film!)

When the film was projected, I was most pleasantly surprised. I had deliberately chosen old film which had been much projected, on occasions by indifferent projectionists. Although there was still one deep scratch visible, any surface 'rain' had gone and the film seemed steadier and crisper than I had remembered it in a long time.

This was a difficult test and the treatment certainly performed as promised. You get a generous supply of this film elixir in a very well padded box, together with the special velvet cloth (as illustrated) for £1. I can thoroughly recommend using Filmlife, which is available direct from the manufacturer (usual disclaimer) Film Treatment Limited, 54 Marlow Bottom, Marlow, Bucks.

Reproduced from the November 1972 issue of Movie Maker.

![]()

This page was last updated 02 Dec 2002